We Believe Trust

Is The Keystone

Of Business

Is The Keystone

Of Business

OUR MACHINERY

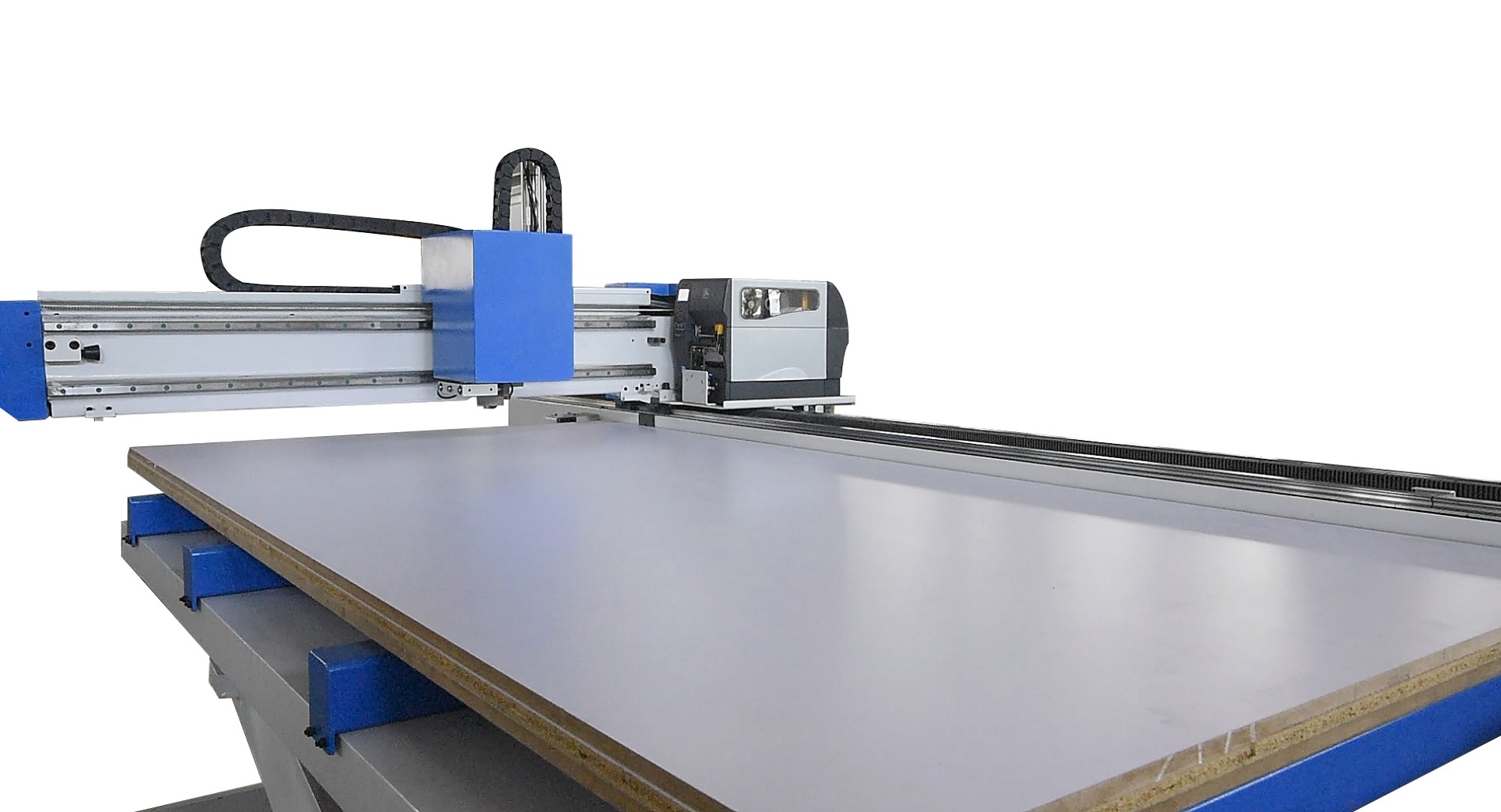

KDT

CNC - 1XXXT Series Labelling Machine

CNC - 1XXXT Series Labelling Machine

CNC - 1XXXT Series Labelling Machine

Application features: automatic correction of plate position, automatic detection of plate height by position sensor, automatic height adjustment of plate height position, automatic labeling, and detection of missing or misplaced labels by sensors; The automated production line used reduces the errors caused by human intervention and improves production efficiency. This equipment is mainly used for the feeding and labeling of various types of man-made boards. 1. Loading frame can bear 4500kg; 2. Stacked board thickness can be stacked 500mm height; 3. Automatically snapping function to ensure accurate labeling; 4 feeding pre-positioning function, to achieve a feeding step in place; 5. The labeling configuration push mechanism can automatically correct the position of the labeling board; 6. The detection device can detect whether the missed label is mislabeled.

FEATURE:

Side Push Wheel

Computer Control

Auto Aligner Unit

SPEC:

KN-1409T

Maximum Workpiece Dimension

:

2400 x 1200

Maximum Speed m/min

:

30

Machine Power

:

3.75 KW

KN-1710T

Maximum Workpiece Dimension

:

3050 x 2150

Maximum Speed m/min

:

30

Machine Power

:

3.75 KW

KN-1713T

Maximum Workpiece Dimension

:

4000 x 2150

Maximum Speed m/min

:

30

Machine Power

:

3.75 KW

SIMILAR PRODUCT:

KDT

CNC KN-2XXXE Series

CNC KN-2XXXE Series

KN-2710DE / KN-2170E / KN-2612DE / KN-2612E / KN-2408DE / KN-2408E

KDT

CNC-KN3XXXDT Series

CNC-KN3XXXDT Series

KN-3409DT

KDT

Drilling KN-3019C/E/CM/EM Horizontal Drilling Machine

Drilling KN-3019C/E/CM/EM Horizontal Drilling Machine

KN - 3018E

KDT

Drilling KDT-6XXXK Series NC Boring Machine

Drilling KDT-6XXXK Series NC Boring Machine

KDT 6042K

KDT

KD-6XXS Series NC Drilling Machine

KD-6XXS Series NC Drilling Machine

KD 612S

KDT

Drilling KN 2312 Series NC Boring Machine

Drilling KN 2312 Series NC Boring Machine

KN-2312E

KDT

Drilling KN 2309 Series NC Drilling Machine

Drilling KN 2309 Series NC Drilling Machine

KN 2309E

KDT

Drilling KN-2XXXS Series Boring Machine

Drilling KN-2XXXS Series Boring Machine

KN-2312S

KDT

Drilling KD-6XX Series Six Side Drilling Machine

Drilling KD-6XX Series Six Side Drilling Machine

KD-612

KDT

Drilling KN-3XXX Series Horizontal Drilling Machine

Drilling KN-3XXX Series Horizontal Drilling Machine

KN-3018C

KDT

Drilling KDT-6XXTH Series

Drilling KDT-6XXTH Series

KDT-6042 / KDT-6052

KDT

Drilling KDT 6XXXD Drawer Plate Series

Drilling KDT 6XXXD Drawer Plate Series

KDT 6002D / KDT 6022D / KDT 6032D

KDT

Drilling KDT-6XXXTM Series

Drilling KDT-6XXXTM Series

KDT-6352 / KDT-6462

KDT

Drilling KDT-6XXXS High Speed Series

Drilling KDT-6XXXS High Speed Series

KDT-6042S / KDT-6062S

KDT

Drilling KDT 5XXTL Series Drilling Machine

Drilling KDT 5XXTL Series Drilling Machine

KDT-533 / KDT-535 / KDT-544 / KDT-547

KDT

Drilling KDT 5XXB THL Flip Series

Drilling KDT 5XXB THL Flip Series

KDT-546B / KDT-544B

KDT

Drilling KDT 5XXX THL Series Drilling Machine

Drilling KDT 5XXX THL Series Drilling Machine

KDT-5606 / KDT-5606L / KDT-5610 / KDT-5610L

KDT

Drilling KDT 6XXXD Drawer Plate Series

Drilling KDT 6XXXD Drawer Plate Series

KDT-6002D / KDT-6022D / KDT-6032D

KDT

Sizing Economic Panel Saw KS-8XXE

Sizing Economic Panel Saw KS-8XXE

KS-829E / KS-832E / KS-838E

KDT

Sizing KS-8XXL Rear Loading Series

Sizing KS-8XXL Rear Loading Series

KS-838L / KS-832L

KDT

Sizing KS-8XXH Twin Pusher Rear Loading Series

Sizing KS-8XXH Twin Pusher Rear Loading Series

KS-838H

KDT

Sizing KS-8XX Series NC Panel Saw

Sizing KS-8XX Series NC Panel Saw

KS-829 CP / KS-829P / KS-832CP / KS-838CP / KS-832P

KDT

Sizing Running Saw KS 2XX Series

Sizing Running Saw KS 2XX Series

KS-226 / KS-232

KDT

Sizing Sliding Table Saw KS 1XXP Series

Sizing Sliding Table Saw KS 1XXP Series

KS-132P / KS-132PM / KS-132PV

KDT

Sizing Sliding Table Saw KS-1XX Series

Sizing Sliding Table Saw KS-1XX Series

KS-132 / KS-132C / KS-132D / KS-132K / KS-138

KDT

Edge Bander KE-368JSA(40)

Edge Bander KE-368JSA(40)

KE-368JSA(40)

KDT

Edge Bander KE-486JKP

Edge Bander KE-486JKP

KE-486JKP

KDT

Edge Bander KE-386J Series

Edge Bander KE-386J Series

KE-386JKP

KDT

Edge Bander KE-565J Series

Edge Bander KE-565J Series

KE-565JHS

KDT

Edge Bander KE-396 Series

Edge Bander KE-396 Series

KE-396JS / KE-396JB

KDT

Edge Bander Automatic Double Side Edge Banding KDT-2468J

Edge Bander Automatic Double Side Edge Banding KDT-2468J

KDT-2468J

KDT

Edge Bander Automatic Double Side Edge Banding KDT-2368J

Edge Bander Automatic Double Side Edge Banding KDT-2368J

KDT-2368J

KDT

Edge Banding Machine KE-468J Series

Edge Banding Machine KE-468J Series

KE - 468J

KDT

Edge Bander Machine KE-368J Series

Edge Bander Machine KE-368J Series

KE-368J

KDT

Edge Bander Machine KE-465J Series

Edge Bander Machine KE-465J Series

KE-465J

KDT

Auto Line Equipment KA Transfer Conveyor KA-608

Auto Line Equipment KA Transfer Conveyor KA-608

KA-608

KDT

Auto Line Equipment KA 226 Auto Conveyor Series

Auto Line Equipment KA 226 Auto Conveyor Series

KA-226

KDT

Auto Line Equipment KA-608D Transfer Conveyor

Auto Line Equipment KA-608D Transfer Conveyor

KA-608D

KDT

Auto Line Equipment KA-605 Transfer Conveyor

Auto Line Equipment KA-605 Transfer Conveyor

KA-605

KDT

Auto Line Equipment KA-633D(KDT-933E) Transfer Conveyor

Auto Line Equipment KA-633D(KDT-933E) Transfer Conveyor

KA-633D(KDT-933E)

KDT

Auto Line Equipment KA-633(KDT-933) Transfer Conveyor

Auto Line Equipment KA-633(KDT-933) Transfer Conveyor

KA-633(KDT-933)

KDT

Auto Line Equipment KA-990 Gantry feeding Series

Auto Line Equipment KA-990 Gantry feeding Series

KA-990

KDT

Auto Line Equipment KA-280 Gantry Feeding Series

Auto Line Equipment KA-280 Gantry Feeding Series

KA-280

KDT

Auto Line Equipment KA-998 Frame Feeding Series

Auto Line Equipment KA-998 Frame Feeding Series

KA-998

KDT

Auto Line Equipment KA-288 Frame Feeding Series

Auto Line Equipment KA-288 Frame Feeding Series

KA-288

KDT

Auto Line Equipment KA-996 Frame Feeding Series

Auto Line Equipment KA-996 Frame Feeding Series

KA-996

KDT

Auto Line Equipment KA-286 Frame Feeding Series

Auto Line Equipment KA-286 Frame Feeding Series

KA-286

KDT

Auto Line Equipment KA-532 90° Turning Series

Auto Line Equipment KA-532 90° Turning Series

KA-532

KDT

Auto Line Equipment KA-530 90° Turning Series

Auto Line Equipment KA-530 90° Turning Series

KA-530

KDT

Auto Line Equipment KA-604 Transfer Conveyor

Auto Line Equipment KA-604 Transfer Conveyor

KA-604 / KA-603

KDT

CNC KN-2408K Series

CNC KN-2408K Series

KN-2408K

KDT

CNC KN-2XXXB Series

CNC KN-2XXXB Series

KN-2409B / KN-2408B / KN-2416B

KDT

CNC KN-3XXX Series

CNC KN-3XXX Series

KN-3710 / KN-3710D / KN-3713D / KN-3409 / KN-3409D / KN-3409H / KN-3713

KDT

CNC KP-3013 Series Machine

CNC KP-3013 Series Machine

KP-3013

KDT

CNC KA-9XXX Stacker

CNC KA-9XXX Stacker

KA-9412 / KA-9713 / KA-9409 / KA-9710

KDT

CNC KN-2XXX Series

CNC KN-2XXX Series

KN-2408 / KN-2408D / KN-2408DT / KN-2612D

KDT

CNC KA-2XXX Feeder Series

CNC KA-2XXX Feeder Series

KA-2408 / KA-2412 / KA-2713 / KA-2710